Common scale adjustment screw are divided into three types:

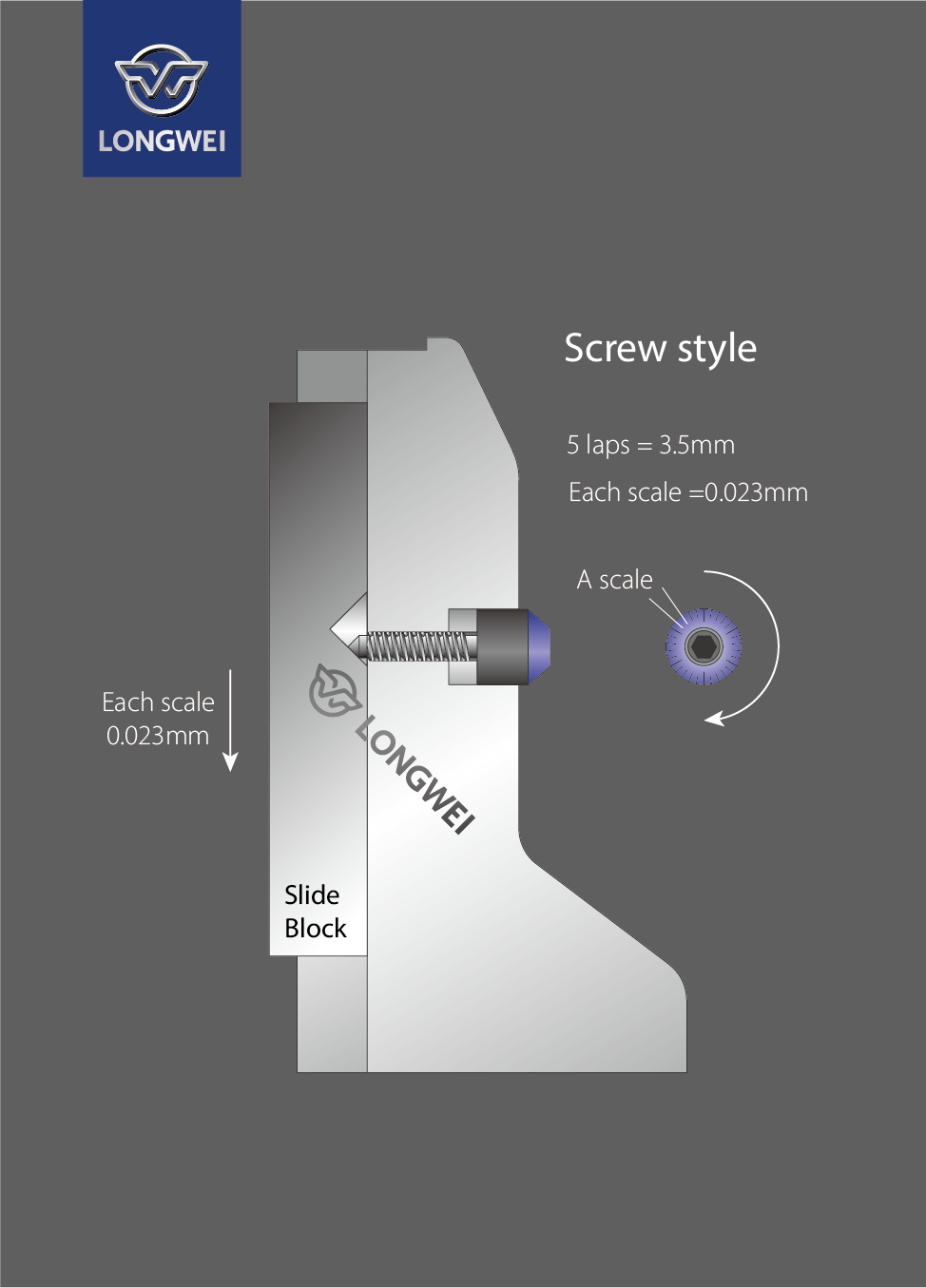

The first kind: screw adjustment type

This type of adjusting screw and scale integrated design, by rotating the scale knob, the screw drives the adjusting scale knob go in and out, through the screw cone top press the slider cone, the slider and the cam which fixed on the slider go down.

Application: Wide application range, high precision adjustment

Advantages: combine adjust accuracy and high accuracy of the scale, novice and master can meet.

Disadvantages: When adjusting the structure fabric, the appearance of tidiness is affected by the different depth of each press needle.

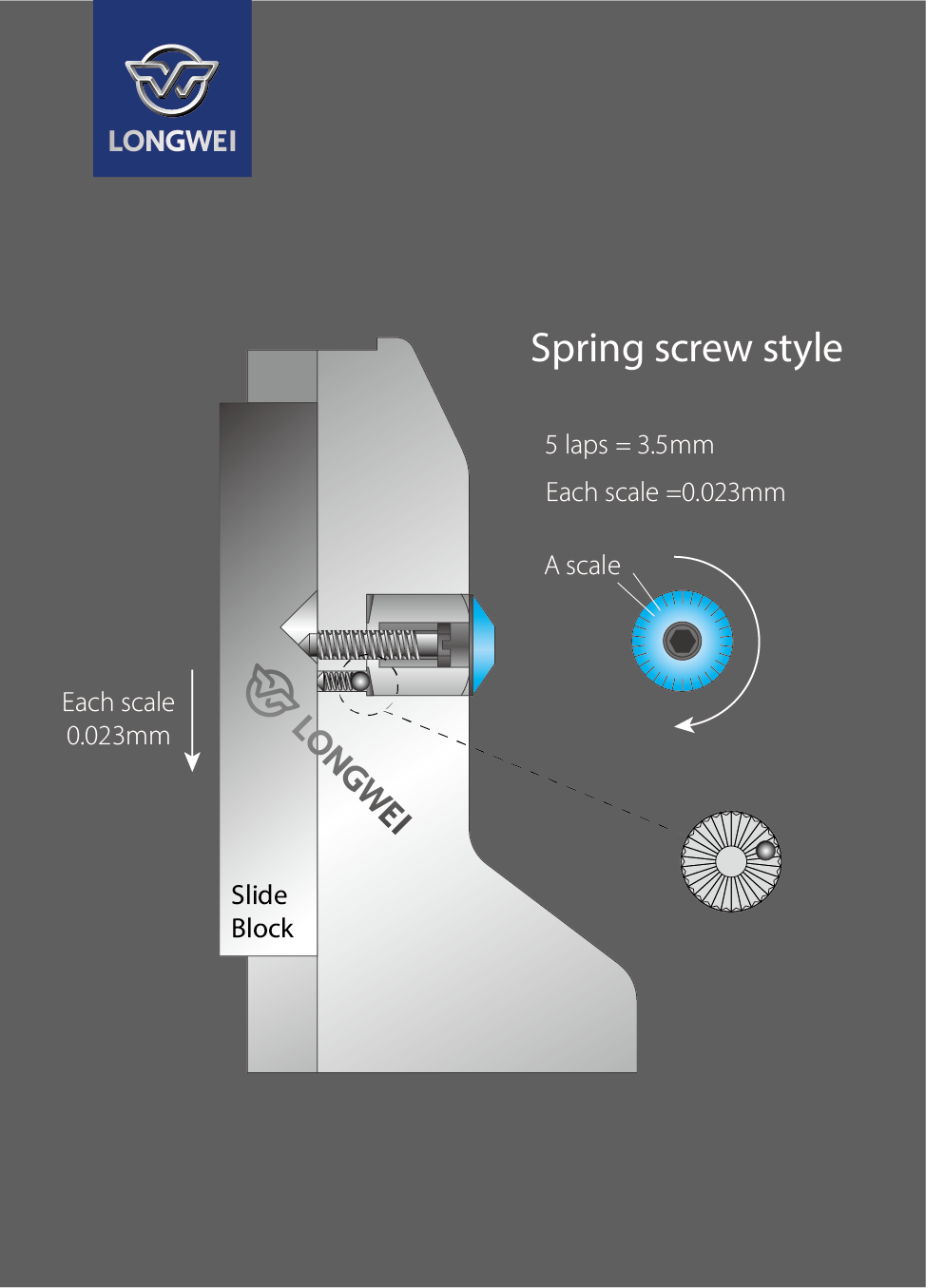

The second: spring screw type

In this type, the sliding block and the cam which fixed on the sliding block are moved down by rotating the built-in adjusting screw and pressing the sliding block cone through the screw cone.

Application: Wide application range, medium and high requirements can be met.

Advantages: Because the scale screw will not move inside and outside, the appearance is more neat, adjust the sound and feel auxiliary.

Disadvantages: the technical requirements of the machine technician is relatively high, or need to use the dial gauge, because it is not an integrated design, the scale screw and the built-in adjustment screw rotate respectively, the scale is easy to shift resulting in the scale is not accuracy.

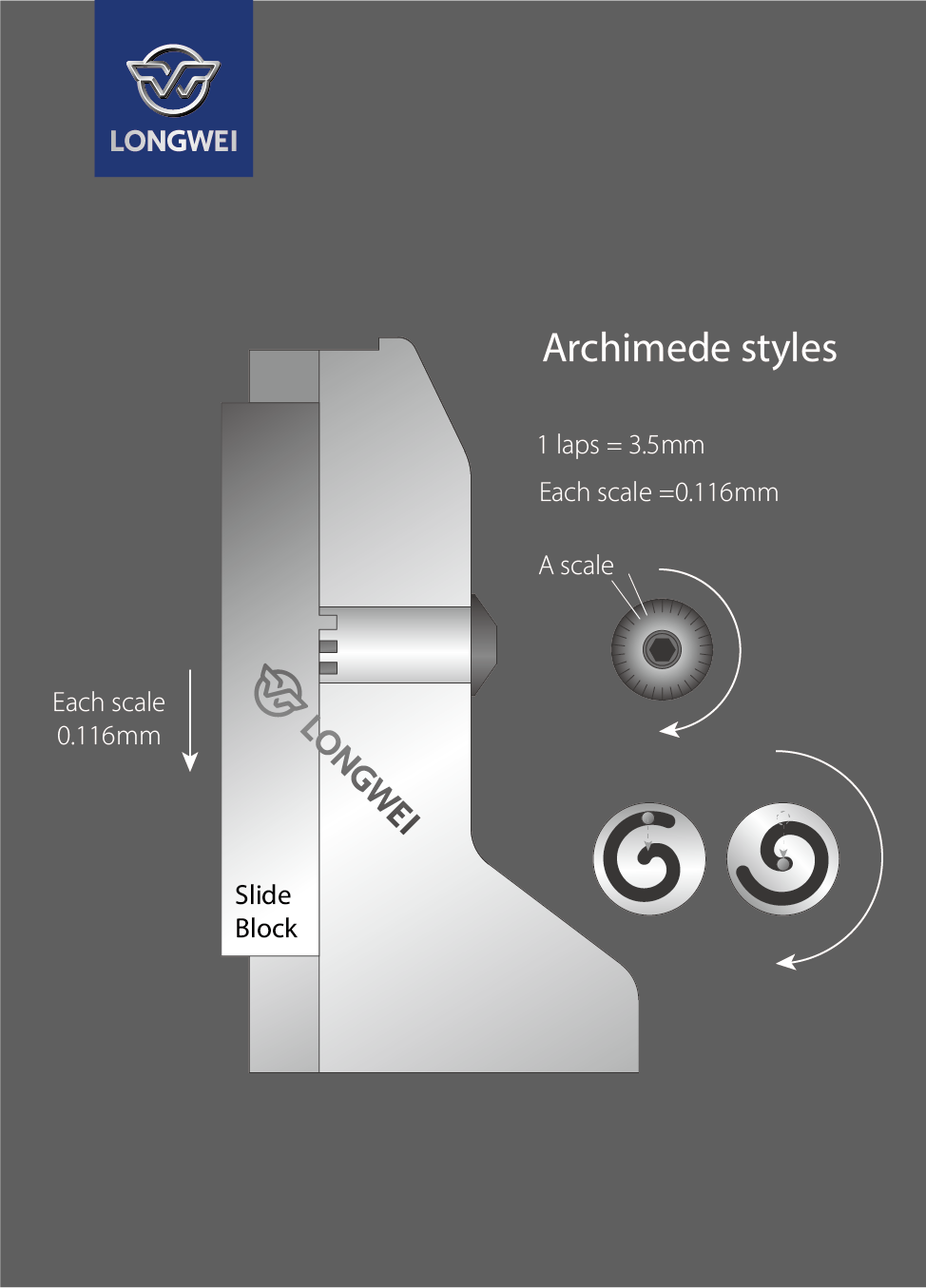

The third: Archimedes style

In his type, the pin on the slide block is driven by the constant speed spiral by rotating the adjusting scale, so that the slide block and the cam which fixed on the slide block move down.Due to structural design reasons, Archimedean adjustment screw travel is short, so each scale slider moving travel is relatively large, if the need to be accurate to 0.01-0.02mm fine gauge or high requirements of cloth is difficult to adjust.

Application: Quick coarse adjustment, suitable for the production of cloth surface insensitive yarn, such as: cotton yarn.

Advantages: simple and fast formachine technician requirements are not high.

Disadvantages: short stroke is difficult to adjust accurately, processing difficulty is easy to produce empty stroke.If the total stroke is reduced to 1mm, each scale can be accurate to 0.033mm, but shortening the stroke also reduces the scope of application of the machine.